Salisbury Station Covered Bridge: Location

- Located 0.60 mi west of the village of Salisbury on the Salisbury Cornwall town line

- Bridge 8 on T.H. 1/T.H.3 over the Otter Creek

- Bridge is co-owned and maintained by the two Towns

- Bridge currently posted for 3 tons

Salisbury Station Covered Bridge: Project History

Original Construction - 1865 Original Construction - 1865

- ±154'-0" single span Plank (Town) Lattice Truss by unknown builders

- Truss patented in 1820 by Ithiel Town, an architect from New Haven, CT

- Web width of ± 5' -0" widest in Vermont

- Constructed at a royalty of $1 /foot

- Constructed to provide Cornwall with a link to railway shipping point in Salisbury

Major Rehabilitation 1969 (State Contract} Major Rehabilitation 1969 (State Contract}

- Pier added at mid-span to level up bottom chords and remove sag. Pier designed for H10

loading.

- Abutments capped, re-pointed and/or faced and new treated shear beams placed

- Other miscellaneous timber repairs

Major Rehabilitation - 1992 (J. Lewandoski) Major Rehabilitation - 1992 (J. Lewandoski)

- Significant timber repairs, including replacing and/or "sistering" all broken or rotted chord

and lattice members (Spruce timbers with hardwood pins)

- Replacement of abutment bedding timbers (White Oak)

- Other miscellaneous repairs

- Repairs based on qualitative assessment

- Cost: Approx. $50,000

Rehabilitation - 2005 (State Contract) Rehabilitation - 2005 (State Contract)

- 1992 - State commissions consultant study for all VT covered bridges, to include

recommendations for long-term preservation

- 1995: McFarland-Johnson study completed for Station Bridge

- Fall 1998: After preliminary meetings, State receives concurrence from both Towns to

proceed as recommended in consultant study

- Recommended option is to rehabilitate structure for moderate traffic

- H10 (20,000 Ibs.) @ Inventory

- H2O (40,000 Ibs.) @ Operating

- Complete deck and floor replacement

- Upgrade truss members where necessary

- Other miscellaneous timber repairs

- Miscellaneous substructure repairs

- New approach rail and signing

- Channel work

Priority of Treatments in CB Preservation Plan Priority of Treatments in CB Preservation Plan

Salisbury Station Covered Bridge: Examples of Current Problem

Areas

Salisbury Station Covered Bridge: Roofing

New Roofinq - Summer 2002 New Roofinq - Summer 2002

- Green standing seam metal roof

- New purlin boards placed where required . Existing rafters retained

- Cost: approx. $25,000

Analyze existing purlins and rafters for snow load. If

structurally adequate, replace in-kind on a piece-by-piece condition assessment. Analyze existing purlins and rafters for snow load. If

structurally adequate, replace in-kind on a piece-by-piece condition assessment.

Other Roofing Considerations Other Roofing Considerations

- Tie beams: Existing 6" x 8" timbers @ 10'-0" spacing

- Lateral Bracing: Existing 6" x 6" timbers in 1 0'-0" bays

- Knee Braces: Existing 2" x 6" timbers @ each tie beam

Analyze bracing system for wind load. If structurally

adequate,

replace in-kind on a piece-by-piece condition assessment. Analyze bracing system for wind load. If structurally

adequate,

replace in-kind on a piece-by-piece condition assessment.

Salisbury Station Covered Bridge: Proposed Truss Repairs

Existing Trusses Existing Trusses

- 3"x12" I.b.c, 2 }2"x11" u.b.c and I.t.c, 3"x11" u.t.c

- 3"x11" lattices

- Significant member replacement and/or sistering in 1992

- All members Spruce-Pine-Fir No.1/No.2 (assumed)

Need further geometry and condition assessment for proper

modeling Need further geometry and condition assessment for proper

modeling

- If feasible, all replacement members will be in-kind

Salisbury Station Covered Bridge: Truss Modeling Options and

Issues

Option 1: Two-Span Continuous Trusses Option 1: Two-Span Continuous Trusses

- 1A: Dead load and structural capacity from original timbers only

- 1B: Dead load from 1992 timbers with no additional structural contribution

- 1C: Dead load from 1992 timbers with additional structural contribution

Option 2: Two Simple Span Trusses Option 2: Two Simple Span Trusses

- Same modeling options as above

Condition assessment critical Condition assessment critical

Live load objectives for rehabilitation Live load objectives for rehabilitation

"1992" members historic? "1992" members historic?

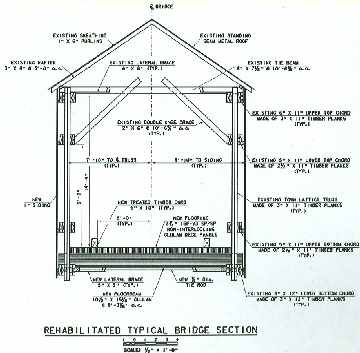

Salisbury Station Covered Bridge: Proposed Floor Replacement

Existing Floor Existing Floor

- 3"x12" runner planks over 2"x 6" diagonal flooring over

- 3"x12" longitudinal deck planking

- 4"x12" transverse floor beams @ varied spacing

- 2"x 6" lateral bracing

Floor beams rate well below proposed loading Floor beams rate well below proposed loading

Proposed Floor Proposed Floor

- 6 3/4" longitudinal glulam deck panels over 1 0 1/2" x 15 1/8" transverse floorbeams spaced

at 5'-3 5/16"

- Floorbeams notched to retain existing vertical clearances

- . Lag screws to stiffen floorbeams for live load deflection

- Sacrificial wearing layer "built-in" to deck thickness

- Curb placement to encourage centering of traffic and pedestrian safety

- New lateral bracing

- Southern Yellow Pine for new glulam members

Salisbury Station Covered Bridge: Project Typical Sections

Salisbury Station Covered Bridge: Miscellaneous Timber

Repairs

Miscellaneous Timber Repairs Miscellaneous Timber Repairs

- Replace damaged planking at portals

- Replace damaged siding

- Other miscellaneous timber repairs

- Fireproofing?

Salisbury Station Covered Bridge: Fireproofing Options

Deterrence: Deterrence:

- Lighting: $6/SF

- Place in upper rafters

- Must be vandal resistant

- Visible alarms

- Fire detection systems: $7/SF

- Linear heat detector wire threaded through bridge

- Camouflage with proper coloring

- Tele-metering

- Used with linear heat detectors, system dials fire

department if there is a fire

Reduce fire potential: Reduce fire potential:

- Intumescent paint: $6.50/SF

- Raises flash point of timber

- vailable in transparent finishes

- Requires re-application every 5-10 years, especially

on decks

- Best suited, but not a 100% guarantee against fire

- Fire retardant treated timbers

- May reduce member strength 10-20%

- Not logical unless treat entire bridge

Arresting the fire: Arresting the fire:

- Hydrants

- Recommended at both ends of bridge

- Pressurized: $3500 ea.

- Need connected water source

- Usually not practical at CB locations

- Dry: $2500 ea.

- Uses water source on site

- Maximum draw height approx. 30 ft.

- Sprinkler System: $10.50/SF

- Placed in roofing

- Water drawn through dry hydrant

- Open head system - no water in it because would

freeze in winter

Cost: Cost:

- Depending on measures taken, may range

from 3-15% of total project costs

- Reduction in insurance premiums

- Do nothing is an option!

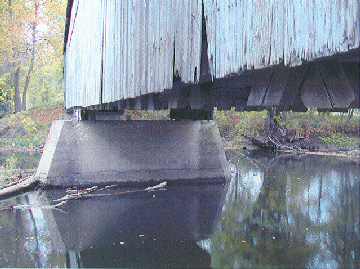

Salisbury Station Covered Bridge: Proposed Substructure

Repairs

Abutment No.1 (West Abutment - Cornwall

Side): Abutment No.1 (West Abutment - Cornwall

Side):

- Existing laid-up stone

- Faced and top leveled in 1969 rehab.

Replace split or checked shear beams and blocking with new

treated timber members Replace split or checked shear beams and blocking with new

treated timber members

Architectural facing? Architectural facing?

Abutment No.2 (East Abutment - Salisbury

Side): Abutment No.2 (East Abutment - Salisbury

Side):

- Existing laid-up stone

- Wingwalls faced and top leveled in 1969 rehab.

- Re-point/face remaining exposed masonry

Replace split or checked shear beams and blocking

with new treated timber members Replace split or checked shear beams and blocking

with new treated timber members

Architectural facing? Architectural facing?

Pier: Pier:

- Existing bent-type pier: Concrete cap on single row of

vertical steel piles constructed new in 1969

Analyze pier for proposed loading considering existing

scour conditions Analyze pier for proposed loading considering existing

scour conditions

Replace split or checked shear beams and blocking

with riew treated timber members Replace split or checked shear beams and blocking

with riew treated timber members

Salisbury Station Covered Bridge: Proposed Approach

Improvements

Approach Rail: Approach Rail:

- Currently no rail on either approach

- Qption 1: Steel backed timber rail

- Qption 2: Heavy-duty steel beam weathering (or galvanized)

rail on timber (or steel) posts with timber offset blocks

- Both are crash tested, standard rail systems

- Construct wingwall extensions for shoulder housing

- Optional rail connection to bridge portal timbers

Other Approach Improvements Other Approach Improvements

- New pavement on both approaches

- Narrow bridge and clearance signing

- Other miscellaneous drive and grading improvements

- Stone fill for bank stabilization

Salisbury Station Covered Bridge: Proposed Channel Work

Channel Work Channel Work

- Remove debris at upstream side of pier

- Stone fill for bank stabilization

|

Original Construction - 1865

Original Construction - 1865

Major Rehabilitation 1969 (State Contract}

Major Rehabilitation 1969 (State Contract}

Major Rehabilitation - 1992 (J. Lewandoski)

Major Rehabilitation - 1992 (J. Lewandoski)

Rehabilitation - 2005 (State Contract)

Rehabilitation - 2005 (State Contract)

Priority of Treatments in CB Preservation Plan

Priority of Treatments in CB Preservation Plan

New Roofinq - Summer 2002

New Roofinq - Summer 2002

Analyze existing purlins and rafters for snow load. If

structurally adequate, replace in-kind on a piece-by-piece condition assessment.

Analyze existing purlins and rafters for snow load. If

structurally adequate, replace in-kind on a piece-by-piece condition assessment. Other Roofing Considerations

Other Roofing Considerations

Analyze bracing system for wind load. If structurally

adequate,

replace in-kind on a piece-by-piece condition assessment.

Analyze bracing system for wind load. If structurally

adequate,

replace in-kind on a piece-by-piece condition assessment.

Existing Trusses

Existing Trusses

Need further geometry and condition assessment for proper

modeling

Need further geometry and condition assessment for proper

modeling Option 1: Two-Span Continuous Trusses

Option 1: Two-Span Continuous Trusses

Option 2: Two Simple Span Trusses

Option 2: Two Simple Span Trusses

Condition assessment critical

Condition assessment critical Live load objectives for rehabilitation

Live load objectives for rehabilitation "1992" members historic?

"1992" members historic?

Existing Floor

Existing Floor

Floor beams rate well below proposed loading

Floor beams rate well below proposed loading Proposed Floor

Proposed Floor

Miscellaneous Timber Repairs

Miscellaneous Timber Repairs

Deterrence:

Deterrence:

Reduce fire potential:

Reduce fire potential:

Arresting the fire:

Arresting the fire:

Cost:

Cost:

Abutment No.1 (West Abutment - Cornwall

Side):

Abutment No.1 (West Abutment - Cornwall

Side):

Replace split or checked shear beams and blocking with new

treated timber members

Replace split or checked shear beams and blocking with new

treated timber members Architectural facing?

Architectural facing? Abutment No.2 (East Abutment - Salisbury

Side):

Abutment No.2 (East Abutment - Salisbury

Side): Replace split or checked shear beams and blocking

with new treated timber members

Replace split or checked shear beams and blocking

with new treated timber members Architectural facing?

Architectural facing? Pier:

Pier: Analyze pier for proposed loading considering existing

scour conditions

Analyze pier for proposed loading considering existing

scour conditions Replace split or checked shear beams and blocking

with riew treated timber members

Replace split or checked shear beams and blocking

with riew treated timber members Approach Rail:

Approach Rail: Other Approach Improvements

Other Approach Improvements Channel Work

Channel Work Joe Nelson, P.O Box 267, Jericho, VT 05465-0267

Joe Nelson, P.O Box 267, Jericho, VT 05465-0267